ELECTRICAL SAFETY IN WORK PLACE.

What do u need to know about electricity?

All electrical systems have the potential to cause harm. Electricity can be either “static” or “dynamic.” Dynamic electricity is the uniform motion of electrons through a conductor (this is known as electric current). Conductors are materials that allow the movement of electricity through it. Most metals are conductors. The human body is also a conductor.

Static electricity is accumulation of charge on surfaces as a result of contact and friction with another surface. This contact/friction causes an accumulation of electrons on one surface, and a deficiency of electrons on the other surface.

Electric current cannot exist without an unbroken path to and from the conductor. Electricity will form a “path” or “loop”. When you plug in a device (e.g., a power tool), the electricity takes the easiest path from the plug-in, to the tool, and back to the power source. This is also known as creating or completing an electrical circuit.

Injuries due to Electrical Accidents

People are injured when they become part of the electrical circuit. Humans are more conductive than the earth (the ground we stand on) which means if there is no other easy path, electricity will try to flow through our bodies.

There are four main types of injuries: electrocution (fatal), electric shock, burns, and falls. These injuries can happen in various ways:

- Direct contact with exposed energized conductors or circuit parts. When electrical current travels through our bodies, it can interfere with the normal electrical signals between the brain and our muscles (e.g., heart may stop beating properly, breathing may stop, or muscles may spasm).

- When the electricity arcs (jumps, or “arcs”) from an exposed energized conductor or circuit part (e.g., overhead power lines) through a gas (such as air) to a person who is grounded (that would provide an alternative route to the ground for the electrical current).

- Thermal burns including burns from heat generated by an electric arc, and flame burns from materials that catch on fire from heating or ignition by electrical currents or an electric arc flash. Contact burns from being shocked can burn internal tissues while leaving only very small injuries on the outside of the skin.

- Thermal burns from the heat radiated from an electric arc flash. Ultraviolet (UV) and infrared (IR) light emitted from the arc flash can also cause damage to the eyes.

- An arc blast can include a potential pressure wave released from an arc flash. This wave can cause physical injuries, collapse your lungs, or create noise that can damage hearing.

- Muscle contractions, or a startle reaction, can cause a person to fall from a ladder, scaffold or aerial bucket. The fall can cause serious injuries.

Qualified Personnel vs. Unqualified Personnel

For the purposes of electrical safety related work practices, there are two types of employees in the work place that may come in contact with electrical equipment on a job site qualified and unqualified.

A Qualified employee is defined as a worker who

- Has been trained to avoid electrical hazards when working on or near exposed energized parts.

- Is familiar with the safety related work practices as required by OSHA standards.

- Is able to distinguish exposed live parts of electrical equipment.

- Is knowledgeable of the skills and techniques used to determine the nominal voltages of exposed parts and components.

An Unqualified employee is defined as a worker who has little or no training regarding electrical hazards. Even though unqualified persons should not be exposed to energized parts, they should be provided with information and training necessary to perform their job in a safe manner and understand the following

- Be familiar with any electrical hazards in the workplace.

- Understand procedures to follow and to protect themselves when they work around electricity.

- Understand which tasks that can only be performed by qualified workers (e.g. maintenance and repairs).

- Know when and how to report electrical problems.

- Know what to do in the event of emergency involving electricity.

- Know how to inspect electrical tools and equipment before use to make sure insulation and wiring are in good condition.

Approach Distance for Qualified Employees

Alternating Current

300V and less Avoid Contact

Over 300V, but less than 750V 1 ft. 0 in. (30.5 cm)

Over 750V, but less than 2kV 1 ft. 6 in. (46 cm)

Over 2kV, but less than 15kV 2 ft. 0 in. (61 cm)

Over 15kV, but less than 37kV 3 ft. 0 in. (91 cm)

Over 37kV, but less than 87.5kV 3 ft. 6 in. (107 cm)

Over 87.5kV, but less than 121kV 4 ft. 0 in. (122 cm)

Over 121kV, but less than 140kV 4 ft. 6 in. (137 cm)

What are some general safety tips for working with or near electricity?

- Inspect portable cord-and-plug connected equipment, extension cords, power bars, and electrical fittings for damage or wear before each use. Repair or replace damaged equipment immediately.

- Always tape extension cords to walls or floors when necessary. Nails and staples can damage extension cords causing fire and shock hazards.

- Use extension cords or equipment that is rated for the level of amperage or wattage that you are using.

- Always use the correct size fuse. Replacing a fuse with one of a larger size can cause excessive currents in the wiring and possibly start a fire.

- Be aware that unusually warm or hot outlets may be a sign that unsafe wiring conditions exists. Unplug any cords or extension cords to these outlets and do not use until a qualified electrician has checked the wiring.

- Always use ladders made with non-conductive side rails (e.g., fiberglass) when working with or near electricity or power lines.

- Place halogen lights away from combustible materials such as cloths or curtains. Halogen lamps can become very hot and may be a fire hazard.

- Risk of electric shock is greater in areas that are wet or damp. Install Ground Fault Circuit Interrupters (GFCIs) or RCCB (Residual Current Circuit Breaker) as they will interrupt the electrical circuit before a current sufficient to cause death or serious injury occurs.

- Make sure that exposed receptacle boxes are made of non-conductive materials.

- Know where the panel and circuit breakers are located in case of an emergency.

- Label all circuit breakers and fuse boxes clearly. Each switch should be positively identified as to which outlet or appliance it is for.

- Do not use outlets or cords that have exposed wiring.

- Do not use portable cord-and-plug connected power tools with the guards removed.

- Do not block access to panels and circuit breakers or fuse boxes.

- Do not touch a person or electrical apparatus in the event of an electrical accident. Always disconnect the power source first.

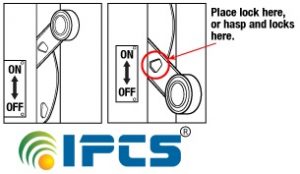

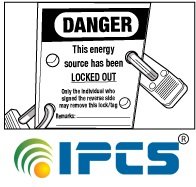

Applying Lockout/Tag-out Devices

All employees whose work involves hazardous energy sources must be trained in lockout/tag out procedures.

Before performing service or maintenance work on machines, turn them off and disconnect them from their energy sources. To further ensure employee safety, use lockout and tag out energy-isolating devices.

The following sections provide information on lockout/tagout procedures. In addition to the procedures in this manual, Texas State University maintains a University Lockout/Tag out Procedures for the control of hazardous energy. A copy of this document is available from the Facilities Department and shall be referenced when preparing to work with high energy devices.

Only authorized employees may apply lockout/tag out devices. The following steps provide a brief outline of approved application procedures:

- Notify employees that the equipment requires service or maintenance and is scheduled for shutdown and lockout/tag out.

- Use established procedures to identify the type, magnitude, and hazards of the equipment’s energy source. Make sure you know the proper methods for controlling the energy source.

- If the equipment is currently operating, shut it down using normal shutdown procedures.

- Isolate the equipment from its energy source by activating the energy-isolating device(s). Either lockout or tag out the energy-isolating device(s).

- Dissipate or restrain stored and residual energy using methods such as grounding, re positioning, blocking, bleeding, etc. (Capacitors, springs, hydraulic systems, and air/gas/water pressure system may contain stored or residual energy.)

- Ensure that all employees are removed from the equipment. Then, test the equipment for successful isolation by attempting to operate it.

Using Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) refers to items typically worn by a worker to provide protection from recognized hazards. Depending on the job task to be performed, PPE for the electric power industry generally includes safety glasses, face shields, hard hats, safety shoes, insulating (rubber) gloves with leather protectors, insulating sleeves, and flame-resistant (FR) clothing. Additional PPE, such as fall protection equipment, respirators, chemical-resistant or cut-resistant gloves, and chaps, may be required, depending on the results of the hazard assessment

Personal protective equipment is an integral part of Electrical safety requirements. It serves to provide adequate protection against hazards of different severity levels that personnel are likely to be exposed during their routine jobs at the substation. It is the responsibility of the employer to accurately assess the various risks in the work environment, determine their severity and accordingly choose PPEs that offer the best protection. The choice of PPE must be based on the findings of the most recent arc flash analysis and risk assessment exercise to provide effective cover.

PPE Required

Most utilities and industrial firms spell out PPE requirements, usage and maintenance instructions as a part of their safety protocol. We must make sure the PPE available on site which include:

Hard hats (with full/partial brims as necessary)

Safety glasses with side shields

Face masks/shields

Suitable footwear (safety/steel-toed boots, rated dielectric footwear)

Insulating gloves (rated, used along with leather/cloth linings for shock protection)

Insulated tools

Electrical/insulation blankets

Live-line tools/hot sticks