What is OPC

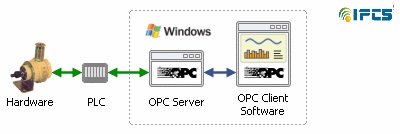

Open Platform Communications (OPC) is a series of standards and specifications for industrial telecommunication. In other words, OPC is a software interface standard that allows Windows programs to communicate with industrial hardware devices.

The OPC standard is a series of specifications developed by industry vendors, end-users and software developers. These specifications define the interface between Clients and Servers, as well as Servers and Servers, including access to real-time data, monitoring of alarms and events, access to historical data and other applications.

The OPC standard is a series of specifications developed by industry vendors, end-users and software developers. These specifications define the interface between Clients and Servers, as well as Servers and Servers, including access to real-time data, monitoring of alarms and events, access to historical data and other applications.

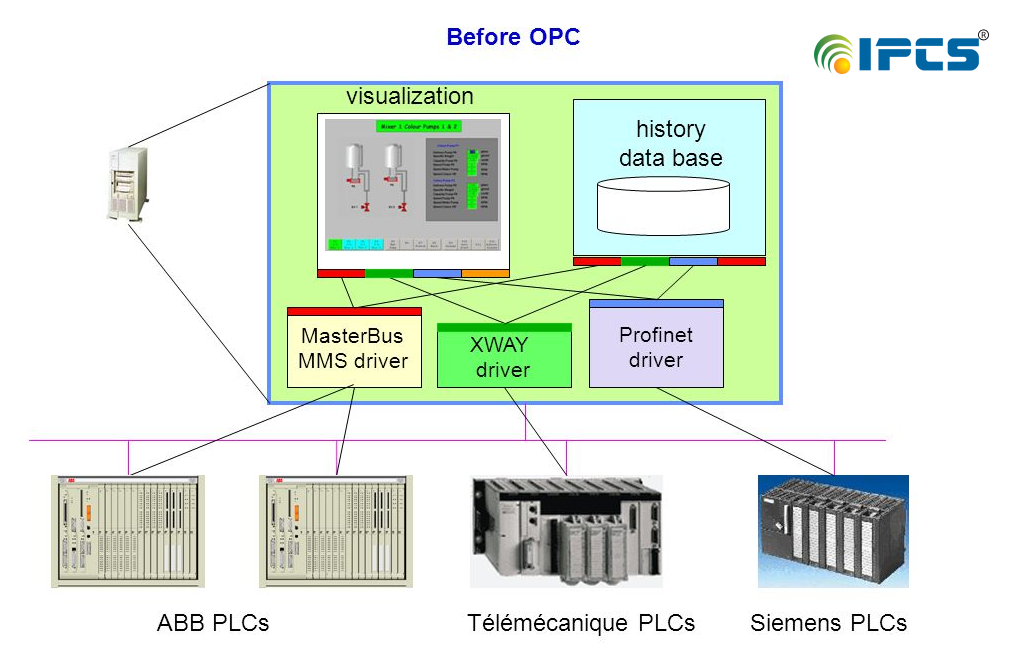

Before OPC

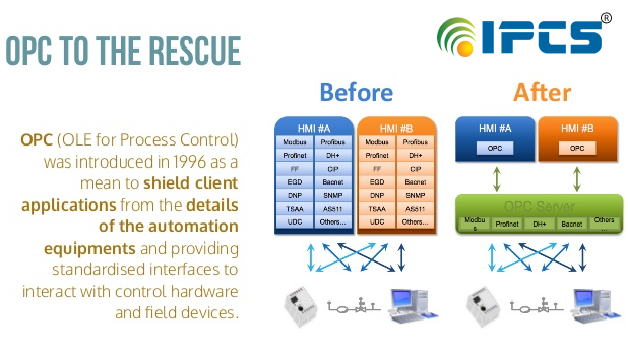

The OPC standard brings plug-and-play connectivity to industrial automation. Before OPC, application vendors had to develop custom software for every third-party device and application that needed to be integrated into the automation system. With OPC, you get open connectivity across products, independent of your hardware or software platform. OPC defines the standard way of sharing real-time data, historical data, and alarms & events, reducing your integration and total life-cycle costs for system implementations.

Breakthrough for OPC

An industrial automation industry task force developed the original standard in 1996 under the name OLE for Process Control.

After the initial release in 1996, the OPC Foundation was created to maintain the standard. As OPC has been adopted beyond the field of process control, the OPC Foundation changed the name to Open Platform Communications in 2011. The change in name reflects the applications of OPC technology for applications in building automation, discrete manufacturing, process control, and many others.

OPC Classic

The first version of the OPC standard was based on a Microsoft technology for exchanging data between software components, called DCOM (Distributed Component Object Model), a subset of COM (Component Object Model). The original meaning of OPC was OLE for Process Control, which refers to OLE (Object Linking and Embedding), a Microsoft COM desktop technology for embedding and linking documents and other software objects.

In 1998, the OPC Foundation began to convert the original specification to web services.

There are three OPC Classic specifications:

There are three OPC Classic specifications:

OPC Data Access (OPC DA) defines OPC client-server technology and how software can read and write data, as well as the data types and structures available.

OPC Alarms and Events (OPC AE) describes the ways OPC server software can monitor systems and send alarms to client software.

OPC Historical Data Access (HDA) defines the queries and analytics that can be applied to the historical time-stamped data collected from devices.

Digitally transforming assets is a priority for manufacturers in the age of Industry 4.0. Computers and automation technology have come together to create game-changing possibilities and the global marketplace has been turned completely on its head. To compete globally, manufacturers are looking to connect factory machines to the cloud and become more flexible in their production to meet customer expectations. However, they’re resistant to making changes to their machines because doing so seems too risky, expensive, insecure, and intrusive, especially given the wide variety of devices on the plant floor. Recent technological developments, however, address these barriers to smart factory transformation, helping companies get connected to the cloud to manage data and devices, gain insights, and leverage machine learning capabilities. The backbone of this connectivity is the Open Platform Communications Unified Architecture (OPC UA), which simplifies interoperability and enables manufacturers to get a head start on transforming their assets into smart factories.

Recent technological developments, however, address these barriers to smart factory transformation, helping companies get connected to the cloud to manage data and devices, gain insights, and leverage machine learning capabilities. The backbone of this connectivity is the Open Platform Communications Unified Architecture (OPC UA), which simplifies interoperability and enables manufacturers to get a head start on transforming their assets into smart factories.

OPC Unified Architecture

OPC UA is an extensible SOA framework designed to support a wide range of platforms, from embedded microcontrollers to cloud infrastructure. It provides security through encryption, authentication, and auditing. It goes beyond OPC Classic by adding on-demand capabilities, the ability to discover servers and other systems on a network, and an address-space scheme meant to allow more complex data structures.

The OPC Foundation provides downloadable COM proxy wrappers for integrating OPC UA and OPC Classic products.

As of late 2017, the OPC Foundation claimed 470-member companies around the world. Leaders in the software, hardware, industrial automation, machine-to-machine (M2M), smart energy and discrete- and process-manufacturing sectors are members. Among the well-known brands are Honeywell, IBM, Microsoft, Pfizer, Rockwell, Samsung, SAP, and Siemens. In recent years, vendors of Industrial Internet of Things (IIoT) technology have used OPC UA in product demonstrations, and in 2016 the OPC Foundation announced a partnership with the Object Management Group and its program, the Industrial Internet Consortium, to integrate the two standards for IIoT.