Electronic Pills

We are familiar with a wide range of sensors in the field of electronics. They are used widely in the various experiments research activities too. This microelectronic pill is such a sensor with a number of channels and is called as a multichannel sensor. As the name implies, this sensor is a pill. That is it meant to go inside the body and to study the internal conditions.

Earlier it was when the transistor was invented, that radiometry capsules were first put into use. These capsules made use of simple circuits for studying the gastrointestinal tract. Some of the reasons that prevented their use were their size and their limitation of not to transmit through more than a single channel. They had poor reliability and sensitivity.

The lifespan of the sensors was also too short. This paved the way for the implementation of single-channel telemetry capsules and they were later developed to overcome the demerits of the large size of laboratory type sensors.

The semiconductor technologies also helped in the formation and thus finally the presently seen microelectronic pill was developed. These pills are now used for taking remote biomedical measurements in researches and diagnosis. The sensors make use of the microtechnology to serve the purpose. The main intention of using the pill is to perform an internal study and recognize or detect the abnormalities and the diseases of the gastrointestinal tract. In this GI (Gastro-Intestinal) tract we cannot use the old endoscope as the access is restricted.

BLOCK DIAGRAM

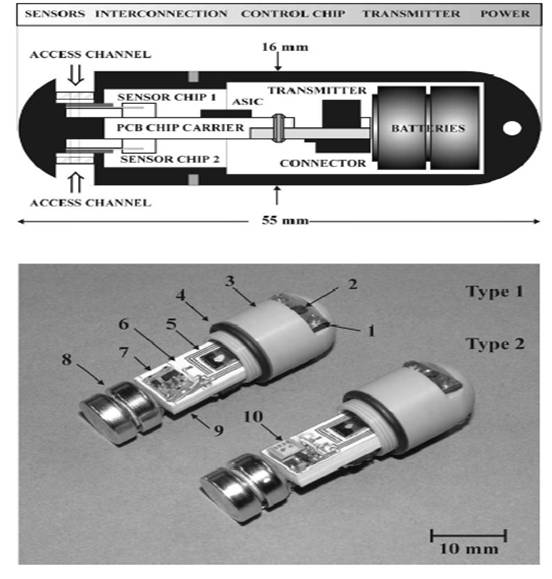

The design of the microelectronic pill is in the form of a capsule. The encasing it has is biocompatible. Inside this are multi-channel (four channels) sensors and a control chip. It also comprises a radio transmitter and two silver oxide cells. The four sensors are mounted on the two silicon chips. In addition to it, there are a control chip, one access channel and a radio transmitter.

The four sensors commonly used are a temperature sensor, pH ISFET sensor, a dual-electrode conductivity sensor, and a three electrode electrochemical oxygen sensor.

Microelectronic pill consists of 4 sensors (2) which are mounted on two silicon chips (Chip 1 & 2), a control chip (5), a radio transmitter (STD- type1-7, type2-crystal type-10), silver oxide batteries (8), 1-access channel, 3-capsule, 4- rubber ring, 6-PCB chip carrier.

The microelectronic pill consists of a machined biocompatible (non-cytotoxic), chemically resistant polyether-terketone (PEEK) capsule and a PCB chip carrier acting as a common platform for attachment of sensors, ASIC, transmitter & batteries. The fabricated sensors were each attached by wire bonding to a custom made chip carrier made from a 10pin, 0.5pitch polymide ribbon connector.

The connector in turn was connected to an industrial STD, flat cable plug (FCP) socket attached to the PCB carrier chip of the microelectronic pill, to facilitate the rapid replacement of the sensors when required. The PCB chip carrier was made from 2 STD. 1.6 mm-thick fiberglass boards attached back to back epoxy resin which maximized the distance between the 2 sensor chips.

The sensor chips are connected to both sides of the PCB by separate FCP sockets, with sensor chip 1 facing the top face, with the sensor chip 2 facing down. Thus, the oxygen sensor on chip 2 had to be connected to the top face by three 200nm copper leads soldered onto the board. The transmitter was integrated in the PCB which also incorporated the power supply rails, the connection points to the sensors, as well as the transmitter & the ASIC & the supporting slots for the capsule in which the carrier is located.

There are basically 4 sensors mounted on two chips- Chip 1 & chip 2. On-chip

1. Sensor chip 1

An array consisting of both temperature sensor & pH sensor platforms was cut from the wafer and attached to 100-µm- thick glass coverslip cured on a hot plate. The plate acts as a temporary carrier to assist handling of the device during level 1 of lithography when the electric connection tracks, electrode bonding pads are defined. Bonding pads provide electrical contact to the external electronic circuit.

Chip 1 is divided into two- LHS unit having the temperature sensor silicon diode, while the RHS unit comprises the pH ISFET sensor.

DT-670-SD Silicon Diode Features

- It measures the body core temperature.

- Also compensates with the temperature induced signal changes in other sensors.

- It also identifies local changes associated with tissue inflammation & ulcers.

ISFET:

Ion Selective Field Effect Transistor ISFET; this type of electrode contains a transistor coated with a chemically sensitive material to measure pH in solution and moist surfaces. As the potential at the chemically active surface changes with the pH, the current induced through the transistor varies. A temperature diode simultaneously monitors the temperature at the sensing surface. The pH meter to a temperature compensated pH reading correlates the change in current and temperature.

2. Sensor chip 2

The Level 1 pattern (electric tracks, bonding pads, and electrodes) was defined in 0.9µm UV3 resist by electron beam lithography. A layer of 200nm gold (including an adhesion layer of 15nm titanium and 15nm palladium) was deposited by thermal evaporation. The fabrication process was repeated.

Oxygen sensor detection principle

Most portable or survey instruments used for workplace evaluation of oxygen concentrations make use of “fuel cell” type oxygen sensors. “Fuel cell” oxygen sensors consist of a diffusion barrier, a sensing electrode (cathode) made of a noble metal such as gold or platinum, and a working electrode made of a base metal such as lead or zinc immersed in a basic electrolyte (such as a solution of potassium hydroxide).

Control Chip

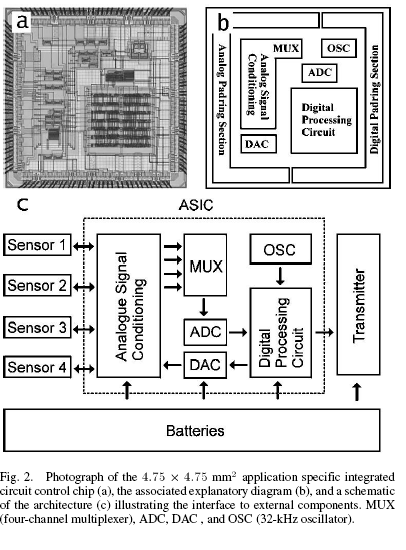

ASIC (Application-Specific Integrated Circuit) is the control chip that connects together the external components of the microsystem.

Application-Specific Integrated Circuit (ASIC)

An integrated circuit designed to perform a particular function by defining the interconnection of a set of basic circuit building blocks drawn from a library provided by the circuit manufacturer.

ASIC is a novel mixed-signal design that contains an analog signal conditioning module operating the sensors, 10-bit ADC & DAC converters & a digital data processing module. An RC relaxation oscillator (OSC) provides the clock signal.

The analog module is based on the AMS (Automated Manifest System), which offer a lot of power saving scheme (sleep mode) & a compact IC design. The temperature circuitry biased the diode at a constant current so that a change in temperature would result in the corresponding change in diode voltage.

The pH ISFET sensor was biased as a simple source & drain follower at constant current with D-S voltage changing with threshold voltage & pH. Conductivity circuit operated at direct current measuring the resistance across the electrode pair as an inverse function of solution conductivity. An incorporated potentiostat operated the amperometric oxygen sensor with a 10-bit DAC controlling the working electrode potential with respect to the reference.

The analog signals were sequenced through a MUX prior to being digitized by the ADC. The bandwidth for each channel was limited by the sampling interval of 0.2ms.

Radio Transmitter

It’s assembled prior to integration in the capsule using discrete surface mount components on a single-sided PCB. The footprint of the standard transmitter measured 8*5*3mm including the integrated coil (magnetic) antenna. It’s designed to operate at a transmission freq. of 40.01MHz at 20˚C generating a signal of 10kHz bandwidth. A second crystal stabilized transmitter was also used. This unit is similar to the free running STD transmitter, having a transmission frequency limited to 20.08MHz at 20˚C, due to crystal used. Pills incorporating the STD transmitter are Type 1, whereas the pills having crystal stabilized unit is Type 2. The transmission range was measured as being 1m & the modulation scheme FSK (Frequency Shift Keying), with a data rate of 1kb/s.

ADVANTAGES

- It is being beneficially used for disease detection & abnormalities in the human body. Therefore, it is also called a MAGIC PILL FOR HEALTH CARE.

- Adaptable for use in corrosive & quiescent environment.

- Micro Electronic Pill utilizes a PROGRAMMABLE STANDBY MODE, So power consumption is very less.

- It has a very small size, hence it is very easy for practical usage.

- High sensitivity, Good reliability & Lifetimes.

- A very long life of the cells (40 hours), Less Power, Current & Voltage requirement (12.1mW, 3.9mA, 3.1 V).

- Less transmission length & hence has zero noise interference

APPLICATIONS

- Environmental & industrial applications, such as the evaluation of water quality, pollution detection, fermentation process control & inspection of the pipelines.

- The integration of radiation sensors

- The application of indirect imaging technologies such as ultrasound & impedance tomography.

- Improve the detection of tissue abnormalities

- Radiation treatment associated with cancer & chronic inflammation.