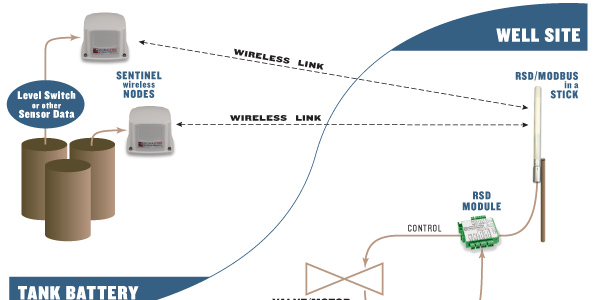

Remote Shutdown System (RSDS) can shut down wells or other assets remotely with the fail-safe logic necessary for wireless operation of critical systems. In challenging environments, such as oil fields, equipment often needs to be shut down remotely. For instance, when a tank that collects oil or water from several wells becomes full, wells must be shut down to prevent overflow. Because of the oil-field layout, the decision to shut-in a well (usually conducted near the tanks) is often made far away from the actual wells. For this type of monitoring and control, SignalFire wireless telemetry offers the remote shutdown system (RSDS), which can shut down assets remotely with the fail-safe logic necessary for wireless operation of critical systems. Eliminating the need for costly conduit runs, this long-range (3+ miles) wireless telemetry system can be configured with either a PLC monitoring system (shown) or a gateway-controlled standalone system that can monitor inputs and generate control commands autonomously. When configured as a PLC-controlled system, a local PLC makes the decision to shut down the remote wells. If monitoring tanks in the oil fields for overflow conditions, tank sensors could be directly connected to the PLC that monitors data and decide if the tank is in an alarmed state. Alternatively, the data could be sent wirelessly, with the PLC obtaining tank-level data from the Gateway. The PLC, then, determines whether the well should be operating or shut-in, and sends the proper command to the shutdown nodes located at the well site. The system interfaces with any type of sensor and transmits the data wirelessly to a gateway. When operating autonomously, the gateway generates commands and offloads data to a PLC. The gateway can be configured to additionally send signals to remotely-located shutdown nodes that will shut-in the well. When the Signal Fire RSDS is configured as a PLC-controlled system, a local PLC makes the decision to shut down the remote wells. If monitoring tanks in the oil fields for overflow conditions, tank sensors could be directly connected to the PLC that monitors data and decide if the tank is in an alarmed state. Alternatively, the data could be sent wirelessly, with the PLC obtaining tank-level data from the Gateway. The PLC, then, determines whether the well should be operating or shut-in, and sends the proper command to the shutdown nodes located at the well site. Both RSDS communication systems support a large number of wireless sensors and incorporate Signal Fire ’s exclusive Comm Safe software that guards against system failure if wireless communication is interrupted. In addition to being used extensively in upstream oil and gas applications, the RSDS is ideal for water-tank control and industrial situations where tank monitoring and pump control are necessary, says the company. More News & Events on www.ipcsautomation.com PLC SCADA VFD HMI DCS TRAINING QATAR – COCHIN – CALICUT – COIMBATORE – MUMBAI