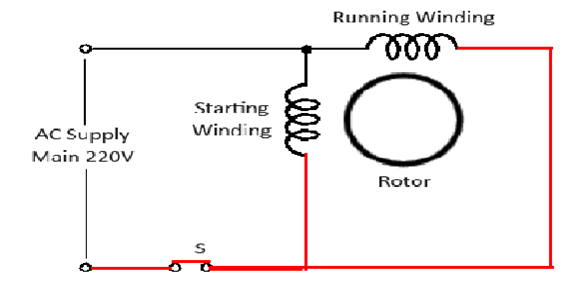

The circuital arrangement of electrical fan mainly having one starting winding and one running winding called stator, and a rotor is used. One capacitor is serially connected with the starting winding, and the supply to these windings are controlled by a switch. By getting the proper supply voltage in the starting winding and running winding then only the rotor will rotate.

Let now consider electrical fan circuital diagram,

We can redraw the above diagram into two. One by without considering the capacitor and one by considering the capacitor serially with the starting winding.

We can consider the above fan circuit diagram without a capacitor, and then we are giving the power supply,

When the switch is closed 230V will be entering into the circuit. And because of the absence of the capacitor, same phase is entering to the starting winding and the running winding. When we are giving the same phase to the two windings, there will not create any magnetic rotation. Hence the rotor will not rotate in this circuit arrangement of the fan without a capacitor.

To create magnetic rotation we have to give two different phase in each winding. But for normal applications, we have single phase connections in home, so we can’t make two phases to give. To overcome this problem we are using Capacitor.

Now we can consider the above fan circuit diagram with a capacitor, and then we are giving the power supply,

Here the capacitor is connected serially with the starting winding. When the switch is closed 230V ac is entering into the circuit, the same phase is entering into the running winding and starting capacitor. The phase which entered into the capacitor will get shifted in phase inside the capacitor and comes out. Now the shifted phase is entering into the starting winding. Due to the different phases in each windings, the magnetic rotation will be created and thus the rotor will rotate.

The capacitor shifting the phase and giving to the starting winding is not only for the starting time. Because continuous phase difference is required for magnetic rotation, and this magnetic rotation will rotate the rotor. Theoretically, the capacitor will shift the phase by 90 degree and due to the resistances occur in the device will reduce the angle. If the capacitor is damaged the shifting angle will reduce some value or go to zero.

If the shifting angle is zero the fan will not rotate, because there will not produce any phase difference and so the magnetic rotation also. And if the shifting angle is reduced, then the magnetic rotation will reduce and so the rotation speed of the rotor will reduce. Because of these reasons, the speed of the fan will decrease and by changing the capacitor we can overcome these problems.

Know more about the automation courses in Kochi that can be helpful and productive.