HART communication protocol

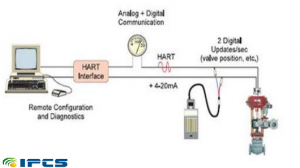

Highway Addressable Remote Transducer(HART) is an open protocol suitable for digital as well as analog purpose in an industrial automation field. It is widely used in process and instrumentation control, which ranges from small applications to highly sophisticated industrial automation applications. It is the most popular as well as the best and smart transition protocol suitable for those users who want to use the legacy 4-20mA signals.

HART Transmitters

HART transmitters are more complex when compared to traditional transmitters. Considering a HART pressure transmitter, It has a pressure input and 4 to 20mA output. In addition to that, there are a number of digital variables and settings in the device. HART communicator or configuration is needed to access those digital parameters. Other than this, there is no other way to access these devices. These HART Pressure transmitters are following HART protocol which is the most popular standard used in the process industry. Here the transfer of the pressure transmitter data by an AC digital signal thus eliminates the need for extra wires and connectors. This AC digital signal uses 4-20mA analog output current as a carrier.

HART Calibration

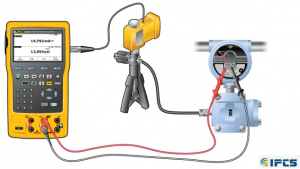

HART Transmitters are needed to be calibrated in order to assure its accuracy. The performance of the instruments is documented over time by collecting data from the calibration and thus completing a report.Considering a HART Pressure transmitter, in order to do the calibration, it should be connected to a control system, or else it needs some other loop supply. Pressure is to be applied at the input, for that it is to be connected to the pressure generator to generate pressure. An accurate calibrator is needed to measure the input pressure and the output mA current.

Sensor trim and Output trim are the important elements in a proper HART calibration. In sensor trim, in order to make the PV agrees with the input applied, a known process variable is applied to the input of the transmitter and thus adjusts the input section. The process variable can be temperature or pressure. In output trim, the transmitter has to output both 4 and 20 mA signal. Then, a precise measurement tool is used to measure these signals and then adjusts the output section to agree with the measurements.