Three phase induction motor is driven by AC supply. Because of low cost and more efficient, in industrial area, this motor is majorly used. It achieves High efficiency and reliable, Maintenance is not much needed, Compare than other Ac motors, Good speed Regulation and initial Torque is High, This is an example for reasonable over load capacity.

Construction

It has majorly two parts, one is Stator and another one is rotor. Stator is nonmoving part, Rotor is a moving part.

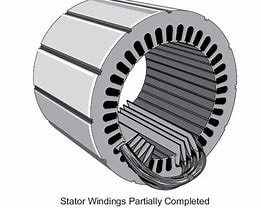

Stator:

Due to Eddy current loss it is made up of high-grade alloy steel lamination. Each lamination are insulated from each other. These laminations are supported in a stator frame of cast iron .Three phase supply is given to the stator terminals whether type of connection is star or delta based on the terminals.

Rotor:

It is a rotating part. This rotor material is constructed same as what we made in stator, The rotor part is present inside the stator, the rotor is directly coupled to the shaft, Based on the rotor connection, induction motor is classified into two types there are two types of induction motor rotors:

- Squirrel cage rotor

- Wound Rotor or Slip Ring Rotor

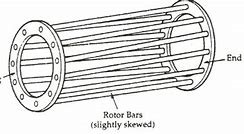

Squirrel Cage Induction Motor

A 3 phase squirrel cage induction motor is a type of three phase induction motor which functions based on the principle of electromagnetism. It is called a ‘squirrel cage’ motor because the rotor inside of it – known as a ‘squirrel cage rotor’ – looks like a squirrel cage. This rotor is a cylinder of steel laminations, with highly conductive metal (typically aluminum or copper) embedded into its surface. When an alternating current is run through the stator windings, a rotating magnetic field is produced.

The skewing of cage rotor conductors offers the following advantages.

- More uniform torque is produce and noise is reduced during operation.

- The locking tendency of the rotor is reduced. During the locking, the rotor and stator teeth attract each other due to magnetic action.

Advantages of Squirrel Cage Induction Motor

- They are low cost

- Require less maintenance (as there are no slip rings or brushes)

- Good speed regulation (they are able to maintain a constant speed)

- High efficiency in converting electrical energy to mechanical energy (while running, not during startup)

- Have better heat regulation

- Small and lightweight

Wound Rotor or Slip Ring Rotor

Construction:

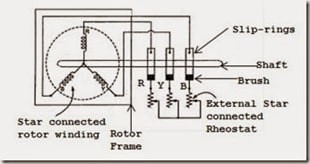

The slip ring induction motor could be used for industrial wires where variable speed and high starting torque are prime requirements. The stator of slip ring induction motor is very much the same as that of the squirrel cage induction motor, but the construction of its rotor is very much different. Stator winding can be either star or delta connected depending upon the design.

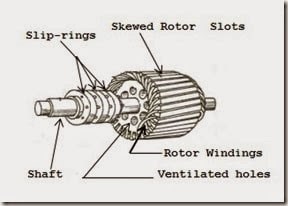

Rotor Construction:

Induction with this type of rotor is having three phase double layer distributed windings. Insulated enameled copper wires are used for coils. The rotor winding is designed as the number of poles of the stator windings. The rotor winding is always wound for three phase winding and star connected.

The three phase windings for rotor is accommodated in these slots of the rotor stampings. For rotor stampings silicon steel laminations are used. Each one end of the three phases is connected in star at the rotor. The remaining terminals are brought out and they are connected to three slip rings. These three slip rings are mounted on the shaft with insulation provided between each other. The brushes are so arranged to rest on three slip rings. External star connected rheostat is connected to these three slip rings.

With this external rheostat connected, helps to increase the starting current the starting torque of the motor at starting. Under normal working condition of this motor, the three slip rings are short circuited by means of a metal collar. The three phase winding are short circuited by this arrangement and hence the wound rotor also acts like the squirrel cage rotor under normal working conditions.

During short circuiting the slip rings, the brushes are automatically lifted from the surface of the slip rings. This is to reduce the friction losses and the wear and tear for the slip ring and brushes. For slip rings high quality phosphor bronze is used.

Windings:

The stator and rotor windings are so arranged for the circulation of air for the purpose of cooling. Enamel insulated copper wires are used for windings. The coils are properly placed in slots to withstand the centrifugal forces and also the stress due to any short circuit. The winding is completely insulated with the use of high-quality varnishes.

When the stator winding of the slip ring motor is connected to the three-phase supply, it produces a rotating magnetic field in the same way as a squirrel cage induction motor. This rotating magnetic field induces voltages in the rotor winding and a rotor current will flow through the closed circuit, formed by the rotor winding, the slip rings, the brushes and the star connected external resistance.

At the tie of starting, the external resistors are set for their maximum value. As such, the rotor resistance is high enabling the starting current to be very low. At the same time, the high resistance rotor circuit increases the rotor power factor, and thereby, the torque developed at the start becomes much higher than the torque developed in squirrel cage motors.

As the motor speeds up, the external resistance is slowly reduced, and the rotor winding is made to be short-circuited at the slip ring ends. Because of the reduced rotor resistance, the motor operates with low slip and high operating efficiency. The motor could be started heavy loads with higher resistance or vice versa. However at increase rotor resistance, the motor’s slip will be greater, the speed regulation poorer and it will have low efficiency. The resistance in the external circuit could be designed and varied to change the speed of the slip ring motor between 50 to 100% of the rated speed. However, the I2R losses in the rotor due to increased resistance is inevitable.