ELECTRICAL CONDUIT

An electrical conduit (EC) is a piping system that is used to carry electrical wiring for either power or communication. These piping systems are commonly referred to as raceways. The ECs are solid and they are used to both house and protect electrical cables and wiring. EC’s may be made from a variety of metal’s, plastics, and fibers, as well as a variety of different sizes.

The term electrical conduit refers to durable tubing or other types of enclosure used to protect and provide a route for individual electrical wiring conductors. Conduit is typically required where wiring is exposed or where it might be subject to damage.

All conduit is installed with compatible fittings (couplings, elbows, connectors) and electrical boxes, usually made of the same or similar material. Conduit must be installed in accordance with the National Electrical Code (NEC) and all applicable local code rules.

There are seven different types of conduit used commonly in residential and light commercial wiring.

Rigid Metal Conduit (RMC) / Rigid Steel Conduit (RSC)

Rigid metal conduit, or RMC, is heavy-duty galvanized steel tubing that is installed with threaded fittings. It is typically used outdoors to provide protection from damage and can also provide structural support for electrical cables, panels, and other equipment. RMC is sold in 10- and 20-foot lengths and has threads on both ends.

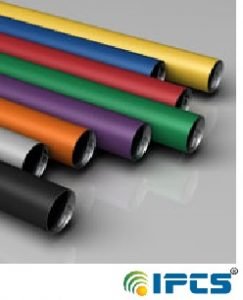

RMCs and RSCs are your heaviest and thickest option, typically made of coated steel, stainless steel, red brass, or aluminum. These pipes can be installed above ground or underground. They are similar in appearance to metal water pipes and are threaded at both ends. The threads on the uncoupled end of the pipes are covered by industry color-coded thread protectors, which protect the threads, keeping them clean and sharp.

Although RMCs and RSCs are generally corrosive resistant, a layer of PVC or zinc (see GRC) can be added in areas that are wet or highly corrosive. If you opt for an organic coating you check for heat restrictions. These types are interchangeable with GRCs.

Intermediate metal conduit, (IMC)

IMC is a thinner, lighter-weight version of rigid metal conduit and is approved for use in all of the same applications as RMC. Because IMC is lighter and easier to work with than RMC, it is more common in new construction.

If you opt for an organic coating, you need to check for heat restrictions. They are interchangeable with GRCs.

Electrical Metallic Tubing (EMT)

Another example of a rigid electrical conduit is EMT (electrical metal tubing), which is most commonly made of galvanized steel but can also be aluminum. EMT is also called “thin-wall” conduit because it is thin and lightweight, especially compared to RMC. EMT is rigid but can be bent with a simple tool called a conduit bender.

EMT is installed with couplings and fittings that are secured with setscrew or compression-type fasteners. The tubing itself is not threaded as is RMC. Common sizes of EMT include 1/2-inch, 3/4-inch, and 1-inch.

EMT is commonly used for exposed indoor wiring runs in residential and light commercial construction. If used outdoors in exposed locations, it must be used with special watertight fittings.

EMTs are not interchangeable with other ECs. EMTs are generally less expensive and lighter than GRCs.

Electrical Non-Metallic Tubing (ENT)

Electrical nonmetallic tubing (ENT) is flexible corrugated plastic tubing that is moisture-resistant and flame-retardant. It is easy to bend and installs with snap-lock or glued plastic fittings. Unlike EMT, non-metallic tubing cannot installed in exposed locations, so it is commonly used inside walls.

In addition to installation in standard wood- or metal-frame walls, ENT can be installed inside a concrete block and covered with concrete. Due to the blue color of one common brand of this conduit, ENT is nicknamed smurf tube.

Rigid Non-Metallic Conduit (PVC)

PVC is made from a combination of plastic and vinyl. PVC pipes can be installed above ground, underground, or encased in cement. PVCs are most commonly used underground. These pipes are lightweight, flexible, impact-resistant, non-conductive, ultraviolet-resistant, and corrosion-resistant. They are popular because they have watertight joints and low installation costs. They are not interchangeable with other ECs.

Rigid polyvinyl chloride (PVC) is similar to plastic plumbing pipe and is installed with plastic fittings that are glued in place. It can be bent after being heated in a portable heater box. Because the conduit tubing and fittings are glued together, the conduit assemblies can be watertight, making PVC suitable for direct burial in the ground for many applications. It is also allowed in corrosive environments.

Flexible Metal Conduit (FMC)

Flexible metal conduit (FMC) is also called “Greenfield,” after the name of its inventor. It has a spiral construction that makes it flexible so it can snake through walls and other structures. Standard FMC is used in dry indoor locations, often for short runs between a wall box and a motor or fixed appliance, such as a garbage disposer.This is your best option for areas that need to sustain large amounts of movement and vibration.

They are found in stainless steel, galvanized steel, or aluminum. They can be waterproof if needed and are installed above ground. The appearance is similar to that of metallic armored cable. They are often used when wiring motors and are not interchangeable with other ECs.

Liquid-tight flexible metal conduit (LFMC)

LFMC is a special type of flexible metal conduit that has a plastic coating and is used with sealed fittings to make it watertight. It is commonly used with outdoor equipment, such as air conditioner units.