WHY DO WE NEED SINGLE PHASE PREVENTERS

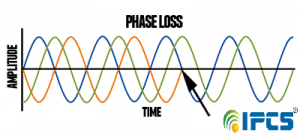

The major cause of maximum motors burnout is overloading which occurs due to unbalance supply or single phasing. Phase failure occurs in case of fuse blown-off, loose connections or loss of phase from supply itself. Single phase preventers is used to protect the induction motor from single phasing fault. The single phasing is the extreme case of unbalancing of stator current. The unbalancing in stator current cause heating in the stator, and it may damage the winding insulation. Single phasing is a very dangerous fault to the electrical motor and which damages the motor stator winding rapidly.

Generally single phasing is nothing but a motor runs when one of the supply is disconnected due to open circuit or improper contact in switch or other electrical equipment failure. Normally, the motor runs with the three phase supply and which takes balance current in each phase winding. Consider one of the fuse has blown. But the motor still in rotating position which tries to rotates in the same speed. At that same time the absence phase current will be shifted to the remaining live phases. Therefore, the current in the other phases increases up to 3 times its normal value instantly. This is called single phasing fault.

The single phasing leads to unbalanced current in the motor stator. The component which is present in this unbalanced current called negative sequence component. These negative sequence component creates the magnetic flux opposite to the main flux. This results in double frequency currents to induce in the rotor to cause its heating.Current sensing single phase preventers works like negative sequence relay. It gives protection up to motor terminals. It Operates on the principle of sensing negative sequence components of the system.

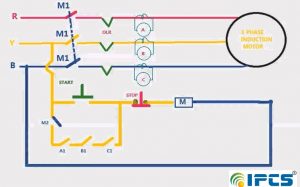

HOW SINGLE PHASE PREVENTERS WORK

Different types of relay manufacturer give addition function such as reverse phasing, unbalance supply and under voltage /over voltage trip with that single phase preventers.

The three number of current transformer is placed in each phase of the power supply. The output of the current transformer is given to the negative sequence filter circuit and which sense the magnitude of unbalance. The filter circuit will be connected to the control circuit. The control circuit sends the trip command to the circuit breaker, if the negative sequence current exceeds the preset value. If the failure of single phase the unbalance current flow in the motor and the current will be sensed by the negative sequence filter. Then the control unit send the trip command to the circuit breaker or other motor isolating mechanism.

Uses of a Single Phase preventers:

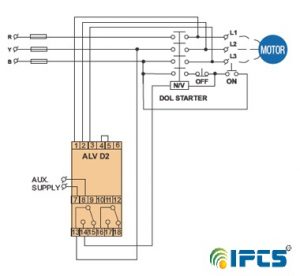

Operates on the principle of sensing negative sequence components of the system.

Suitable for the protection of motors of any H.P.

Protection against single phasing, reverse phasing, unbalance supply.

No separate auxiliary supply required.

Individual trip indication for Single phase preventers, Reverse phasing and Indication for output relay ON

Auto reset type voltage hysteresis gap for tripping on under/over voltage.

Single phase preventers is used for the induction motor for tripping the feeder in case of one of the phases is missing.

The single phase preventers unit monitors the healthiness of all three phases of the supply and trips the feeder if any phase is missing.