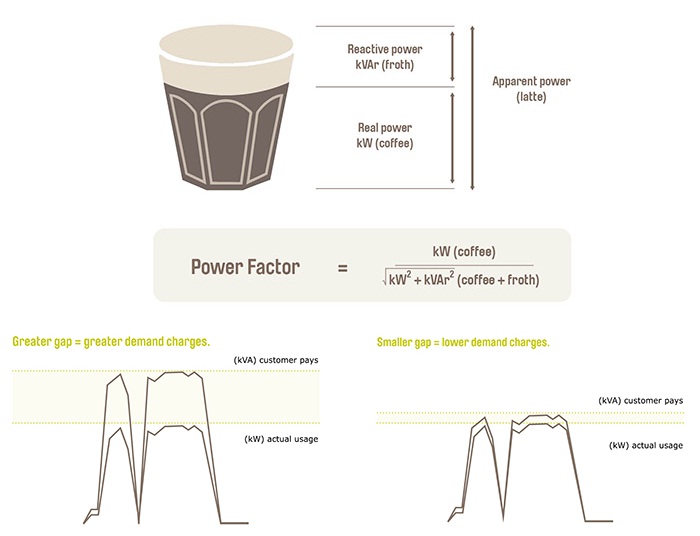

As well as the power that is used in equipment (heating, lighting, driving motors), known as real power, a site may also draw power which is not directly used, known as reactive power. The combination of two is known as apparent power. Power Factor is the relationship between real and apparent power (kVA). If your site has a poor power factor, you could be paying for energy that cannot be used.When you pay for a latte, the last thing you want is more froth than coffee. The same thing can be said about power. Froth on a latte is like wasted energy.Power factor is the ratio of real power to the apparent power flowing to the load from the source. This is an important piece of knowledge for manufacturers because a low power factor raises your plant or factory’s power bill.Taking control of and monitoring Power Factor can lead to reduced kVA demand and therefore reduced electricity costs. Improving Power Factor can lead to savings on your business electricity bill.Installing Power Factor Correction Equipment can be a cost effective measure to reduce your electricity bill.Power factor (PF) is measured between 0 and 1.0 (usually given as a percentage, with 100 percent or 1.0 being unity). If your facility’s PF is below a certain level (typically 95-96 percent), your utility will charge a reactive power fee. This is because a low PF represents an inefficient load source that is drawing reactive (i.e. non-working) power that the utility has to make up for.The best use of power in an AC circuit is when the voltage and current are in alignment. However, much of your electrical equipment is probably delaying as it draws current, meaning that the current and voltage are misaligned and causing it to draw more current to operate.The bottom line is that your PF percentage shows you how much of the total current you are drawing is being used to do real work. For example, a PF of 80 percent means that 20 percent of the current flowing into your facility is non-working power. Power Factor Correction Benefits: Beyond lowering your facility’s electricity bills and avoiding reactive power fees, increasing your facility’s power factor also reduces carbon emissions, reduces I2R losses in transformers and electrical distribution equipment, and reduces heat in cables, switchgear, transformers and alternators which can prolong the lifespan of equipment.

More News & Events on www.ipcsautomation.com

PLC SCADA VFD HMI DCS TRAINING

QATAR – COCHIN – CALICUT – COIMBATORE – MUMBAI