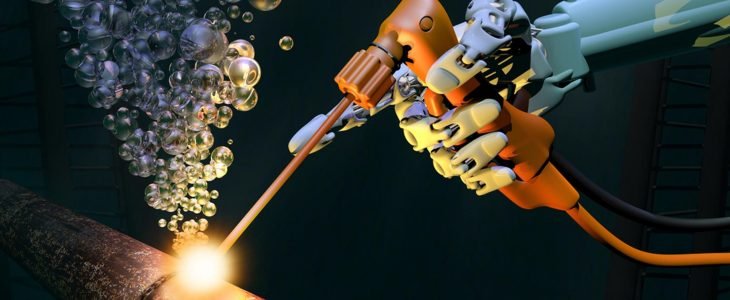

Underwater welding is also called hyperbaric welding. In this process, welding is carried out under high pressure deep under the water. If welding is progressed under dry environment then such welding is called “hyperbaric welding”. If welding is progressed under environment then such welding is called “underwater welding “. Underwater welding is used in offshore structures and pipelines, ships, submarines, and nuclear reactors.

Dry welding is used in the preference of welding under wet water when an excellent quality weld is required. Because of the expanded control in the circumstances which should be possible using when welding heat treatment.

Types of Underwater Welding

There are preferably two types of welding methods are performed on underwater and they are

- Wet Welding

- Dry Welding

Wet Welding

This strategy is done in submerged. This includes the usage of special welding rods and includes a similar procedure applied in typical welding. In wet submerged welding expose the diver and electrode to the water and encompassing components. The diver is provided with supply around 300–400 amps of D.C capacity to charge their electrode, and they weld the desired area with a varied form of arc welding. Because of hydrogen splitting, the procedure is typically constrained to low carbon equal takes, particularly in more depth. Wet welding is finished with similar equipment utilized for dry welding, yet the electrode holders are intended to cool the water and are heavier protecting.

Some of the main advantages of wet welding process are its

- fastest and cheaper welding capability.

- Held in habitat

- The weld area will remain in high tensile strength.

- Ease of access to weld spot

Dry welding

In this procedure, a chamber is fixed around the structure that will be welded. It is loaded up with a gas (a blend of helium and oxygen, or argon), which at that point forces water outside the hyperbaric area. This takes into account a dry situation wherein to perform out the weld. The main advantages of dry welding are It has a high quality of welding, welder or diver safety it’s a type of non-destructive welding and this type of welding has frequent surface monitoring.

The fluctuation of air shields the natural surroundings from toxic fume exhaust. If gases somehow managed to develop inside, hyperbaric welders could choke. What’s more, at more prominent pressure, Divers groups may utilize helium blends for purposes or pressurizing.

Diverse groups may utilize helium to pressurize the cabin with the goal that submerged welders don’t get nitrogen narcosis, or more regrettable, lose consciousness. Helium is additionally lighter than other different gases.